We should be asking the simple question "Is there a better board that minimizes the damage to the ocean?"

Let’s be honest. Not too many people think about the various glassing options for surfboards.

That’s why I’m writing this series. We’re surfers and we rely on unpolluted natural resources to enjoy riding waves. We should be asking the simple question “is there a better board… one that minimizes the damage to what I love so much?” Related, is there a better board that lasts longer than other boards do?

The first two posts in this series were easy. Picking out an alternative surfboard blank isn’t that hard as they are increasingly available. Connecting with your favorite shaper should also be an easy proposition. The thought of the glassing step… made me pause. It felt daunting and what I found out is that it doesn’t have to feel that way.

I’ll make this easy and speak to the surfers out there that just want to know what they should do… and then I’ll geek out with the surf nerds out there.

Short version. Get your board glassed by someone who uses a Bio-based expoxy resin, like “Super Sap” by Entropy Resins.

Entropy’s “Super Sap” Epoxy Resin (as with other petroleum based epoxy resins) is non-toxic, makes a stronger, longer lasting surfboard, and it can be used to glass any kind of blank. Additionally, the “bio-based” content of the ‘Super Sap’ resin significantly cuts the carbon footprint of this resin, which can be a big plus for the fate of our oceans (more on that below). A list of glassers that use this resin can be found here.

Notice I didn’t say “ask your glasser to use Entropy Bio Epoxy Resin.” That’s intentional as this stage in the board-building process is pretty dialed in (low tolerance for change, thin financial margins, etc). Your local glasser may not want to use something new… so find someone who will.

Long version. Understand why a glass job with a smaller impact is important, then get your board glassed by someone who uses a Bio-Based epoxy resin, like Entropy’s ‘Super Sap.’

There are three main reasons you, as a surfer, should seek glassing options that deliver the performance and durability you want but do so with a lower impact to the environments we love so much.

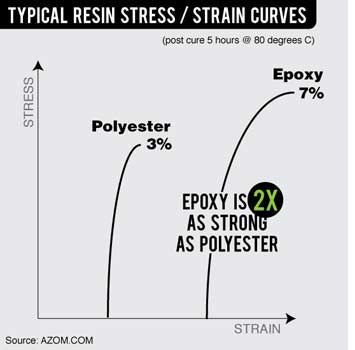

1. For the purposes of a surfboard, Epoxy resin has approximately twice the strength as Polyester resin

Epoxy resin (in general) is better than Polyester resin. It has superior technical performance as the graphic to the right shows. An epoxy resin board can take more “force” (stress) and be “flexed” (strain) more than 2X as much as a polyester resin board before breaking. That means your board will be less likely to get dings of any kind (pressure dings, dings from hitting rocks, dings from being dropped by airline baggage handlers, etc).

The increased strength also means your board will last longer.

Epoxy resins produce stronger surfboards because of their increased adhesion properties, higher tensile strength, and perhaps most importantly, because they can handle significantly more stress & strain before breaking. Short story – this means your next surfboard is way less likely to ding, crack, or snap if it is glassed with epoxy resin, allowing you to surf it harder, faster and longer.

I’ve summarized the other pros and cons of each in the graphic to the right below.

GEEK OUT DETAIL.

- Check out this Material Science web portal for engineers and designers that compares the full story of Epoxy resin vs. Polyester resin.

- Discussion of stress & strain as applied to materials.

2. Entropy’s Bio Epoxy Resin has a much lower CO2 footprint

2. Entropy’s Bio Epoxy Resin has a much lower CO2 footprint

We are surfers; we arrange our schedule and sometimes our lives around maximizing our time in the ocean. It’s important that we don’t kill the golden goose. i.e., No one wants to surf in a dead ocean.

The reason Entropy bio-resin is better than traditional petroleum-based Epoxy or Polyester resins is because it has a notably lower carbon footprint. If you need a quick primer on why our carbon footprint matters to the ocean, check out this article in the New York Times, A world without coral reefs.

The positive benefits to our oceans from sourcing significantly lower carbon intensive products and materials is a home run for why all of this matters.

GEEK OUT DETAIL.

- Use of Entropy Super Sap resin can have a ~50% reduction in CO2 emissions related to the resin vs. traditional petroleum-based Epoxy or Polyester resins.

- Smaller carbon footprint means reduced contribution to negative Climate Change related impacts on the world’s oceans including: sea level rise, ocean acidification/loss of coral reefs, coastal erosion/loss of beaches, etc.).

- Bio-content in Super Sap resin is sourced from waste stream of other industries (biodiesel fuel and paper production)

- Entropy Super Sap is currently the only surfboard resin to have been lab certified for it’s environmental claims and that meets US Gov. requirements for bio-content labeling. Go here for more on this subject.

3. Polyester resin is toxic and has cancer-causing chemicals in it, Entropy’s Bio Epoxy Resins...do not.

Polyester resin has Styrene in it.