Wavestorms don’t scream “eco-friendly,” but they produce less carbon over their lifecycle than poly or epoxy surfboards. Photo: Stan Moniz.

Editor’s Note: This feature was made possible with industry information supplied by AGIT Global.

For a long time now, foam surfboards have held an interesting place in surf culture and thought. Some people love them because they’re hard, if not impossible, to ding, can be used by anyone from beginner to pro, and inject an element of fun into a sport that we have a tendency to take way too seriously. On the other end of things, some people hate foam boards because they’re mass-produced, make surfing “easier,” and, so the story goes, are less environmentally friendly than traditional boards. Well, that last claim just might hold less water than a leaky fiberglass board. Some studies have emerged in the past few years that shine a light on just how environmentally unfriendly the production of fiberglass surfboards are, and how relatively small of an impact producing a foam board can have on the environment, an almost 50 percent reduction in carbon emitted for the production of an eight-foot soft top (53 pounds of CO2) compared to a six-foot polyester foam and resin board (105 lbs. of CO2).

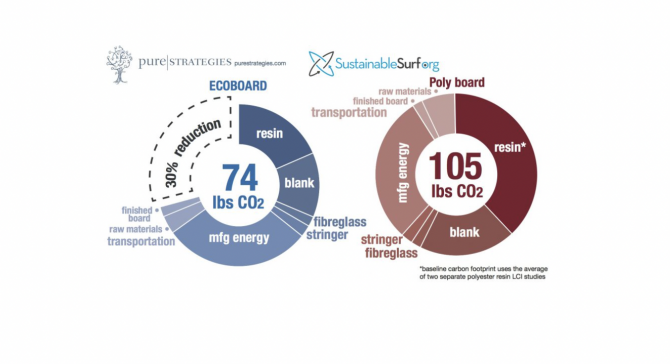

Lifecycle analysis of an ecoboard compared to a traditional poly/fiberglass surfboard. Photo: Sustainable Surf.

The ECOBOARD Project, started by Sustainable Surf in 2012, has done a lot of work around surfboard manufacturing and figuring out how to make it more environmentally friendly. In the process, they produced the “ECOBOARD lifecycle study,” which shows that for every standard polyester shortboard that is made, about 105 pounds of CO2 is emitted in the “lifecycle” process from raw material acquisition to transportation to the surf shop. The greatest impact from a carbon standpoint is the foam and resin that goes into traditional poly/fiberglass surfboards, with only five percent of the carbon footprint coming from the fiberglass, demonstrating that the best way to address the eco-friendliness of a surfboard is to look at finding sustainable alternatives for the resin and foam, arguably the harder materials to replace. “Eco” surfboard manufacturers who use alternatives to fiberglass like hemp or flax are a dime-a-dozen at this point, but the above lifecycle study shows that if they want to make a meaningful impact they’ll need to look at their foam and resin as well.

Lifecycle study done by AGIT Global at their Wavestorm facilities in Taiwan, with numbers verified by Bureau Veritas (full document linked here and here). Photo: AGIT Global.

However, one of the biggest takeaways from this study is that mass production, often seen as producing “soulless” boards and squeezing out the “little guy” of traditional surfboard handshapers and manufacturers is doing the environment a pretty big service at the same time. Numbers just released by AGIT Global, the parent company of Wavestorm, and independently verified by inspection and certification company Bureau Veritas (full document linked here and here), show that an eight-foot Wavestorm produced in their Nantou Taiwan plant only produces about 24.12 kilograms of CO2, or 53.18 lbs. That’s less than half as much CO2 as a six-foot shortboard. And we’re talking about an eight-foot board with almost three-times the literage (assuming an average of 30 liters for a six-foot shortboard, an eight-foot Wavestorm has 86 liters of volume). Pretty impressive.

That being said, straight-up, pound-for-pound, who-produces-the-most-carbon doesn’t tell the full story when it comes to eco-friendliness. There’s the question of how long a board might last before you need to get a new one, whether or not it will shed or flake toxic chemicals into the environment, or if there’s any other consumables necessary to keep it maintained (like resin for fixing dings). Those are a little harder to quantify, but the carbon comparison still goes to show that foam boards might not be as anathema to the environment as we think them to be.

The majority of us are surfing for fun, after all. Photo: Stan Moniz.

Surprisingly, both the foam and fiberglass board studies have shown that transportation is a relatively small part of the carbon footprint, dispelling yet another myth: the oft-heard refrain about how overseas surfboards, foam boards or otherwise, cost more carbon because they need to be transported farther. “Getting your board from your shaper to your favorite surf shop is a relatively small part of the board’s total carbon footprint,” writes Sustainable Surf. “With this in mind, the biggest environmental gains for any type of surfboard will be made by choosing more sustainable materials, minimizing waste from manufacturing and reducing fossil fuel energy use in production.”

In short, while there’s nothing wrong with going to your local shaper, just don’t think you’re doing the environment a service at the same time by avoiding overseas purchases. With any surfboard purchase, if you want to go the eco-friendly route you should definitely do your own research, and be ready to pay a premium in the process. If saving the world was cheap, we’d have done it already.

As surfers, our love for traditional shapes and processes of board building may be holding us back. If we truly want to be as eco-friendly as we can be, we need to step away from traditional poly boards, no matter how “high-performance” they might be, and find different ways to obtain the same characteristics in our surfboards. Or maybe even just settle for “less” performance, and remember that the majority of us are surfing for fun, after all.